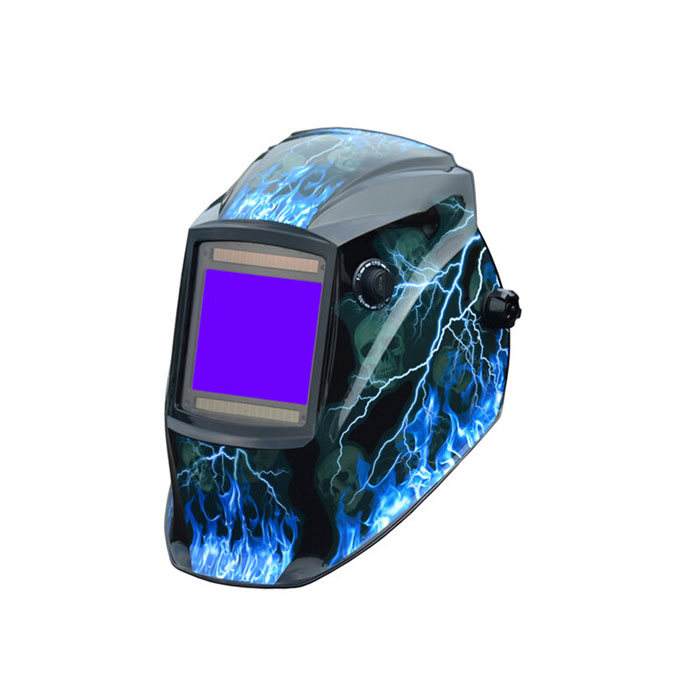

Yakakura Kuona Auto Kusviba Welding Helmet ine CE Chitupa

Tsanangudzo

Iyi ngowani yewelding yehunyanzvi inopa kuchengetedzwa kweziso nekukurumidza sezvo arc inorohwa. Inopa maonero akajeka kana isiri welding asi pakarepo inoshanduka kune inodiwa huwandu hwemumvuri kana sefa kana arc yarohwa. Inogadziriswa musoro bhandi inopa yakagadzika isina-inotsvedza yakakodzera yekushanda-isina maoko.

Yechokwadi Ruvara Technology

Kuderedza lime yegirini tint, sekutarisa nepahwindo rakajeka girazi, iro rinobvumira maonero echokwadi eruvara kuitira kuti uve nemaonero akajeka ezvauri welding.

Cheater Lens Inoenderana

Iyo lens (inotengeswa yakaparadzana) yakaiswa nyore-ingoigadzirisa mukati mewelding mask yako pasi pechivharo chakajeka chakajeka.

Optimal Kuonekwa

Iyo 3.86" × 3.46" nzvimbo yakakura yekutarisa inodzoreredza zvese zvese zvemamiriro ekushanda, izvo zvinovandudza chiono chekuvhara basa rewelding.

Happy Chipo

1*Welding Helmet;1*Outer Protect Lens;1*Inner Protect Lens;1*Chinyorwa

Features

♦ Ngowani yekukweshesa nyanzvi

♦ Optical class : 1/1/1/1

♦ Yakawedzerwa maonero makuru

♦ Welding & Grinding & Cutting

♦ Nezviyero zveEC, ANSI,CSA,AS/NZS

Products details

| MODE | TN350-ADF9100 |

| Optical class | 1/1/1/2 |

| Sefa dimension | 114×133×10mm |

| View size | 98 × 88mm |

| Chiedza chehurumende mumvuri | #3 |

| Rima state mumvuri | Variable Shade DIN5-8/9-13, External Knob setting |

| Kuchinja nguva | 1/25000S kubva kuKwayedza kuenda kwaRima |

| Auto recovery time | 0.2 S-1.0S Kurumidza kusvika Kunonoka, Kugadziriswa kusingatanho |

| Sensitivity control | Yakaderera kusvika kumusoro, Stepless kugadzirisa |

| Arc sensor | 4 |

| Yakaderera TIG Amps Yakayerwa | AC/DC TIG,> 5 amps |

| KUYA basa | Hongu (#3) |

| Cunting shade range | Hongu (DIN5-8) |

| ADF Kuzviongorora | Ehe |

| Low batt | Hongu (Red LED) |

| UV / IR kuchengetedza | Kusvikira kuDIN16 nguva dzese |

| Powered supply | Solar Cells & Replaceable Lithium bhatiri (CR2450) |

| Simba pa/kudzima | Full otomatiki |

| Material | Yakanyanya kukanganisa leval, Nylon |

| Kushanda temp | kubva -10 ℃--+55 ℃ |

| Kuchengetedza temp | kubva -20 ℃--+70 ℃ |

| Warranty | 2 Makore |

| Standard | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Application range | Stick Welding (SMAW); TIG DC∾ TIG Pulse DC; TIG Pulse AC; MIG/MAG/CO2; MIG/MAG Pulse; Plasma Arc Kucheka (PAC); Plasma Arc Welding (PAW); Kukuya. |